Metalcraft: Embracing a Technology Revolution

For many years, robots and advanced AI technology have seemed like a far-fetched dream of the future. However, Iowa’s Manufacturing 4.0 initiative, a strategic plan to bring such technology to the state’s manufacturing industry, is helping this dream become a reality for many Iowa businesses.

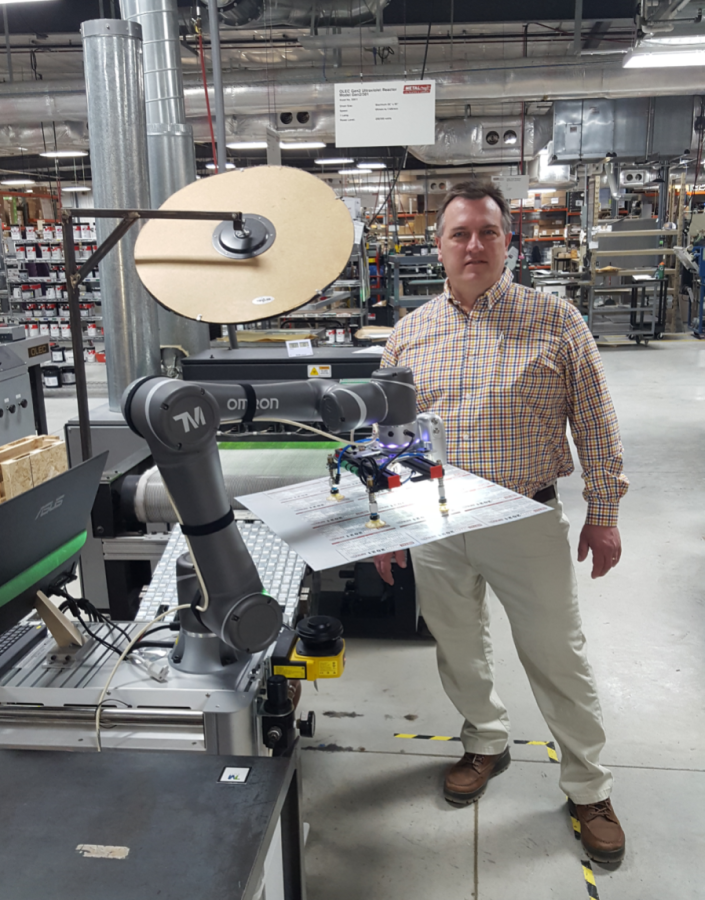

In an effort to maintain Iowa’s place at the top of the manufacturing industry and the state’s ability to compete in the global markets, Iowa’s Manufacturing 4.0 strategies are helping manufacturers improve their production processes through automation and smart technology. One such manufacturer is Mason City’s Metalcraft, manufacturer of ID tags and labels, who last year installed advanced computer software and customization applications as well as purchased a collaborative robot.

"We’re a 70-year-old company and for someone whose been around that long, it’s important to continue to evolve and change with the times, but that’s not always an easy thing to do,” Jim Miller, Metalcraft’s vice president of engineering and quality, said. “We’re all about Iowa manufacturing, its growth and improving the picture in the state and putting a better light on manufacturing in general.”

Last year, the company installed a new enterprise system to improve their ability to use data to make better business decisions as well as enhance their tracking capabilities and cyber security, a priority for a business that works with government agencies and Fortune 500 companies.

Additionally, their OMRON co-bot, a machine designed to easily work alongside humans, was installed on a cart so the company can quickly add more labor when and where it’s needed to keep up with fluctuations in consumer demand. Therefore, the machine switches between spots on the production line either stacking sheets of metal or pushing buttons to program RFID tags.

Such technology has greatly benefitted Metalcraft in a variety of ways, from reducing the paper stacks and decreasing labor costs to receiving real-time information that allows quick decision-making for instant changes and edits on the production line.

As a niche manufacturer, this technology also provides Metalcraft the opportunity to gain a competitive advantage against similar manufacturers in the U.S. and overseas with a better customer experience and fair prices. The new tech also proved to be vital during the global pandemic when it made it possible for most of Metalcraft’s sales team to work from home.

"We know things are changing, and we will continue to make the investments to provide for our members, customers and stakeholders,” Kyle Bermel, Metalcraft’s chief of operations, said. “We want to stay at the forefront of these changes to help us grow now and into the future.”

Manufacturing 4.0 is known as the fourth industrial revolution and includes technologies such as the Internet of Things (IoT), additive manufacturing, advanced robotics, cloud computing, system integration, cybersecurity and more.